Ship Ballast System Design

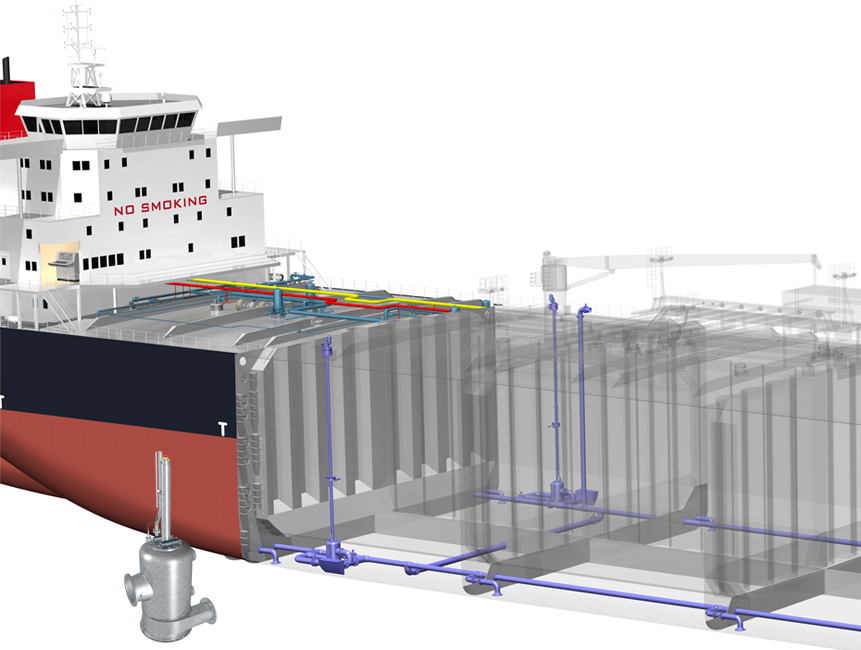

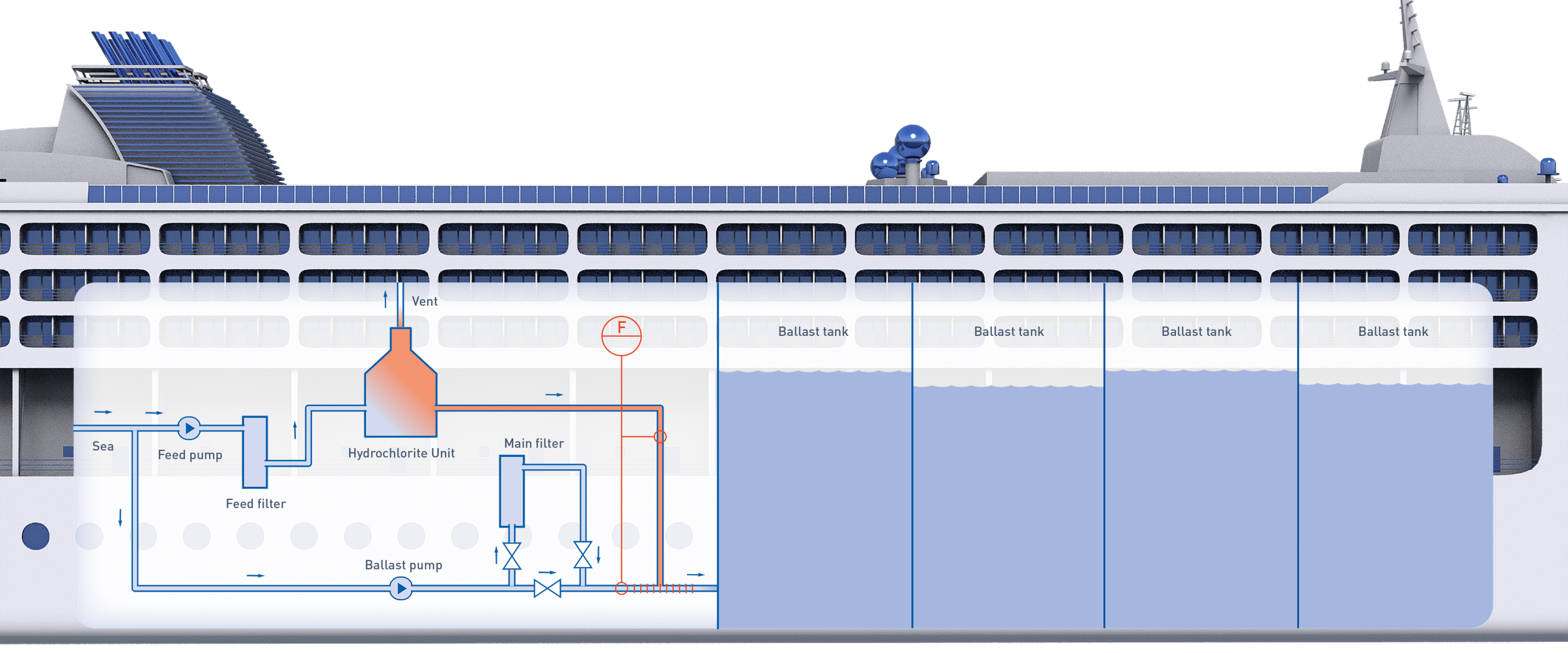

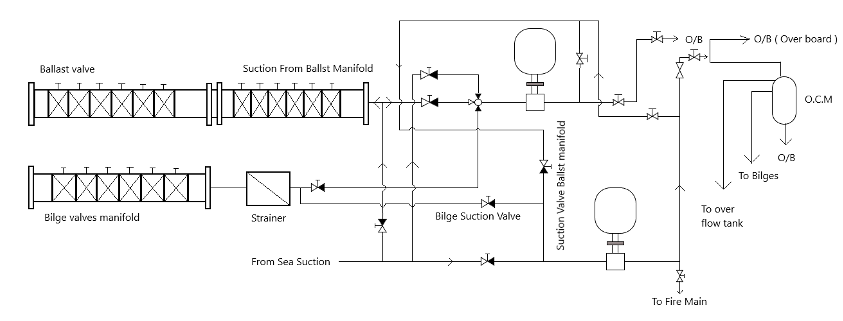

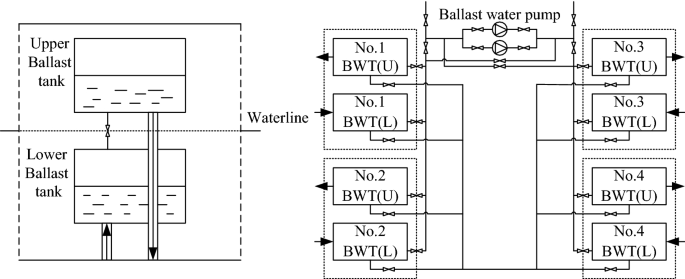

Ship ballast system design. Based on the waste heat availability on an operational tanker a ballast water treatment system was envisaged including a. The capacity of each ballast pump - m3h. More importantly the ships ballast system consists of pumps valves ballast tanks and various annexes their control logic design are not the same.

A general profile and an initial overview of the ships propulsion. It avoids cost from fuel and greenhouse gas emissions but has higher hull build costs operational costs from increasing hull drag and cost incurred from the logistics of handling additional solid. The Computer-Aided Design CAD files and all associated content posted to this website are created uploaded managed and owned by third-party users.

Number of ballast pumps. Water escaped through the crack when the ballast tank was overfilled. The pressure ballast tank Figure 12 consists of a sealed ballast2.

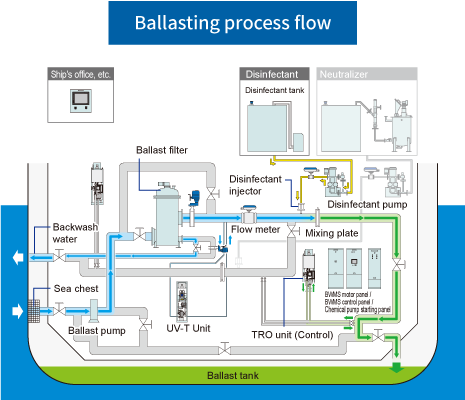

1 Optimized layout of treatment equipment and ballast piping. Because the air in. The application of the ballast water treatment system in new ships should focus on the following aspects 2 4.

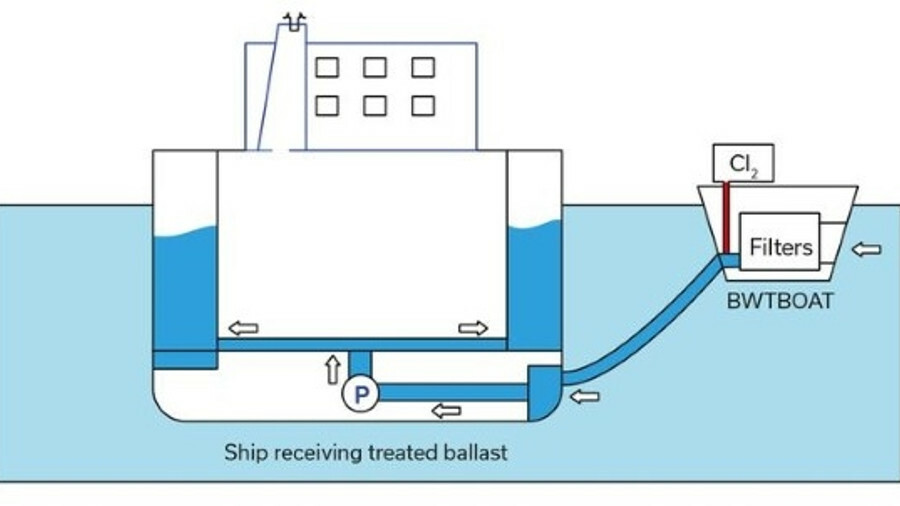

Works with fresh water for ballast water from lakes 6. Tank capable of with standing a significant pressure increase 5 or so. Working with The Columbia Group BIO-UV Group will design a robust ballast water treatment system for ballast pump capacities from 300m3h up to 1000m3h By DA Reporter 20 Jul 2021 The US.

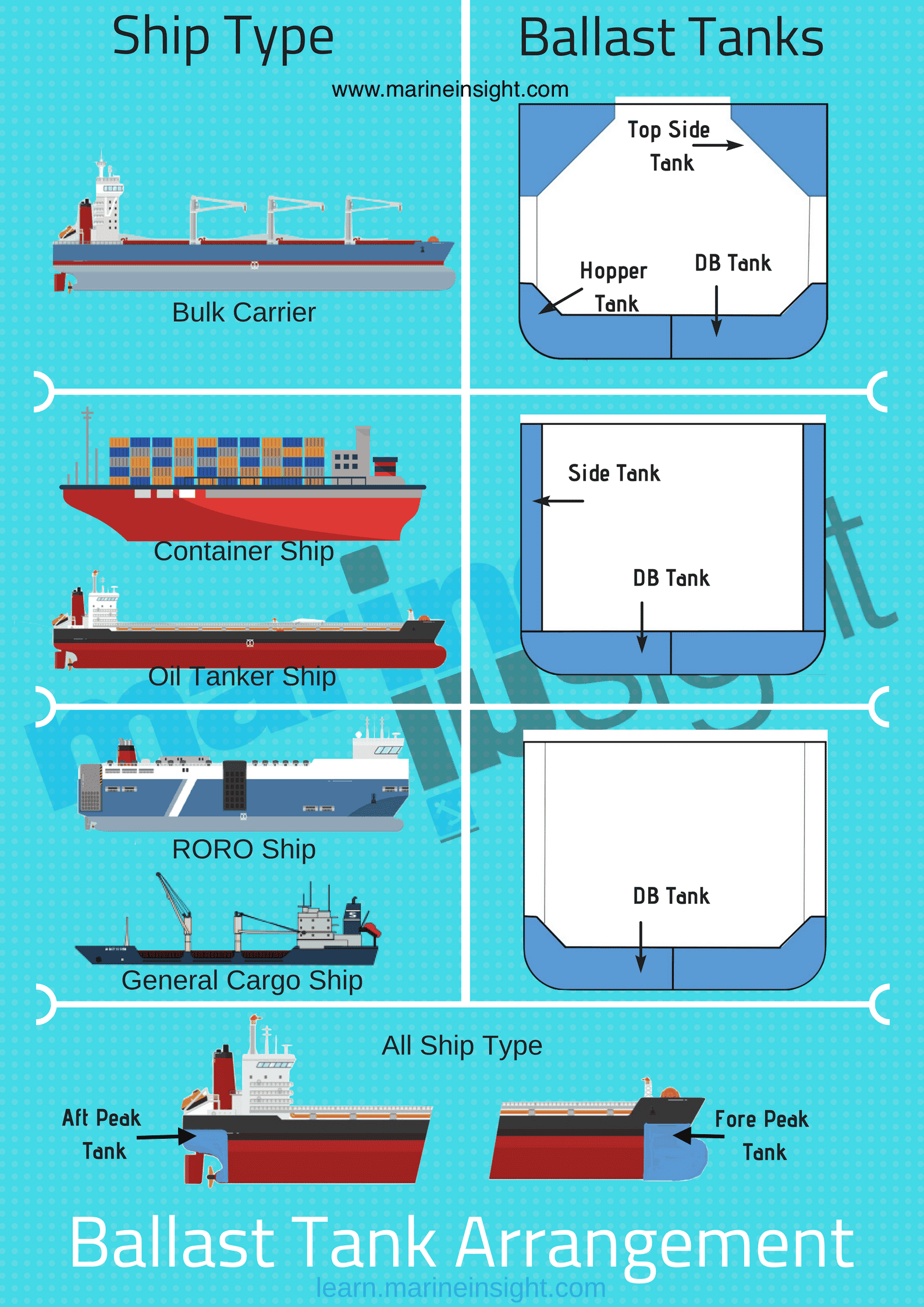

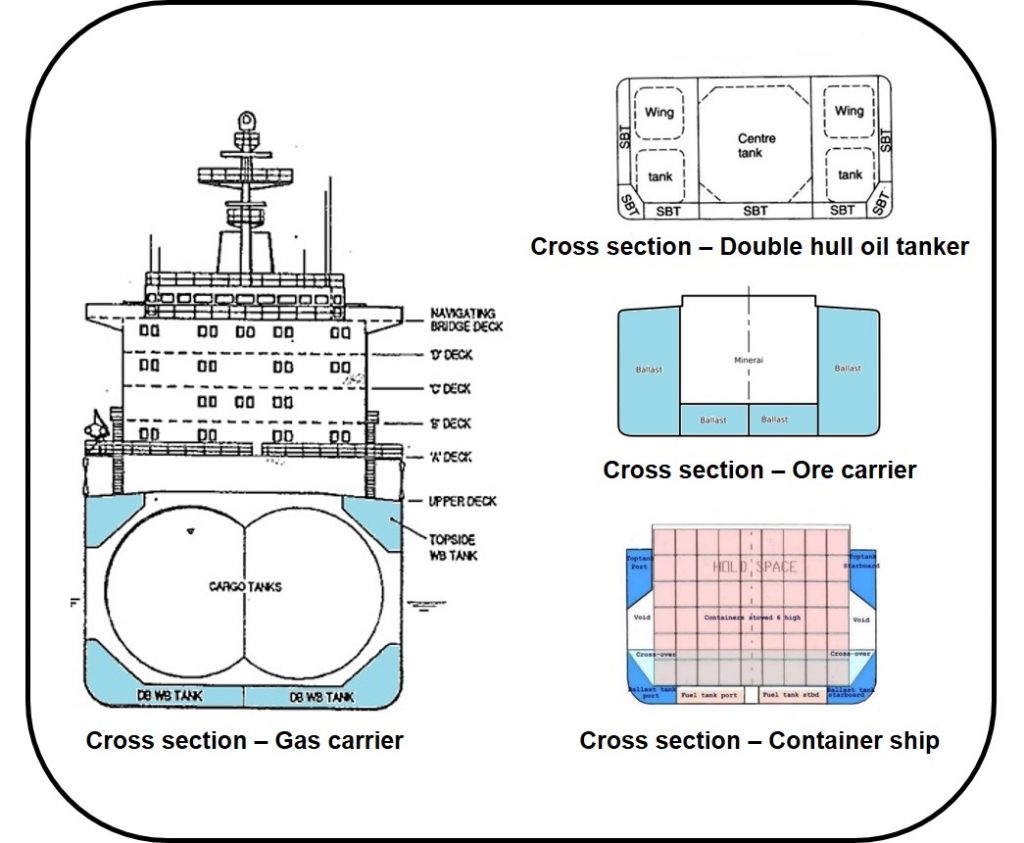

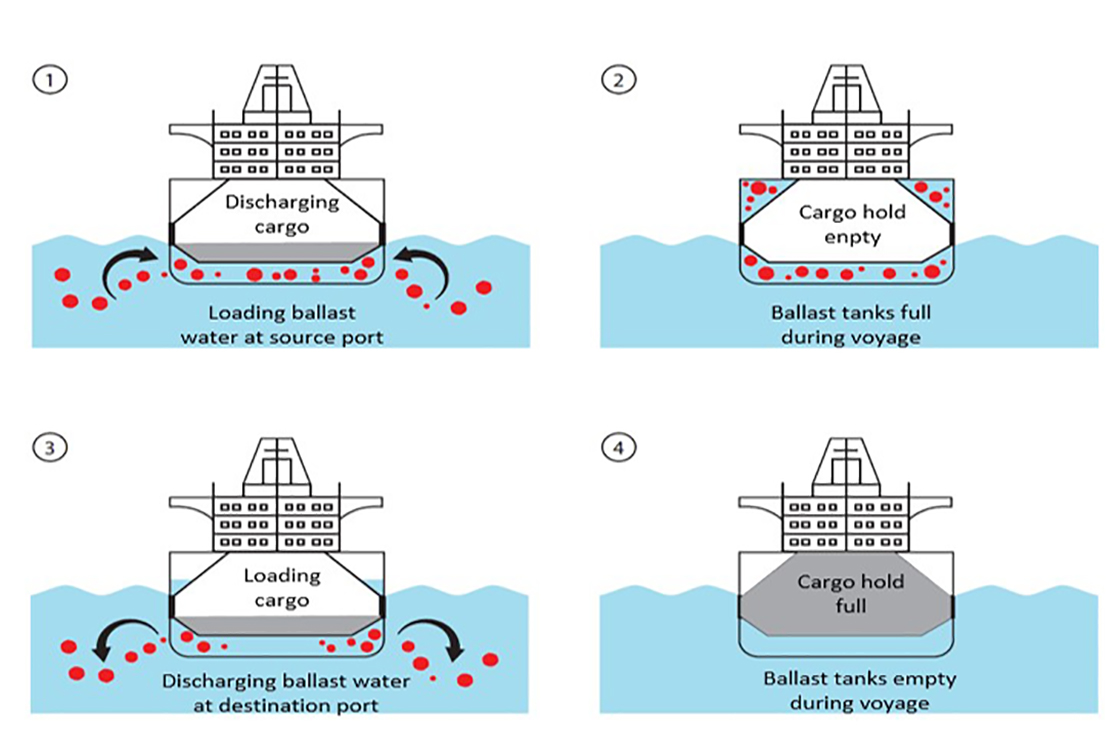

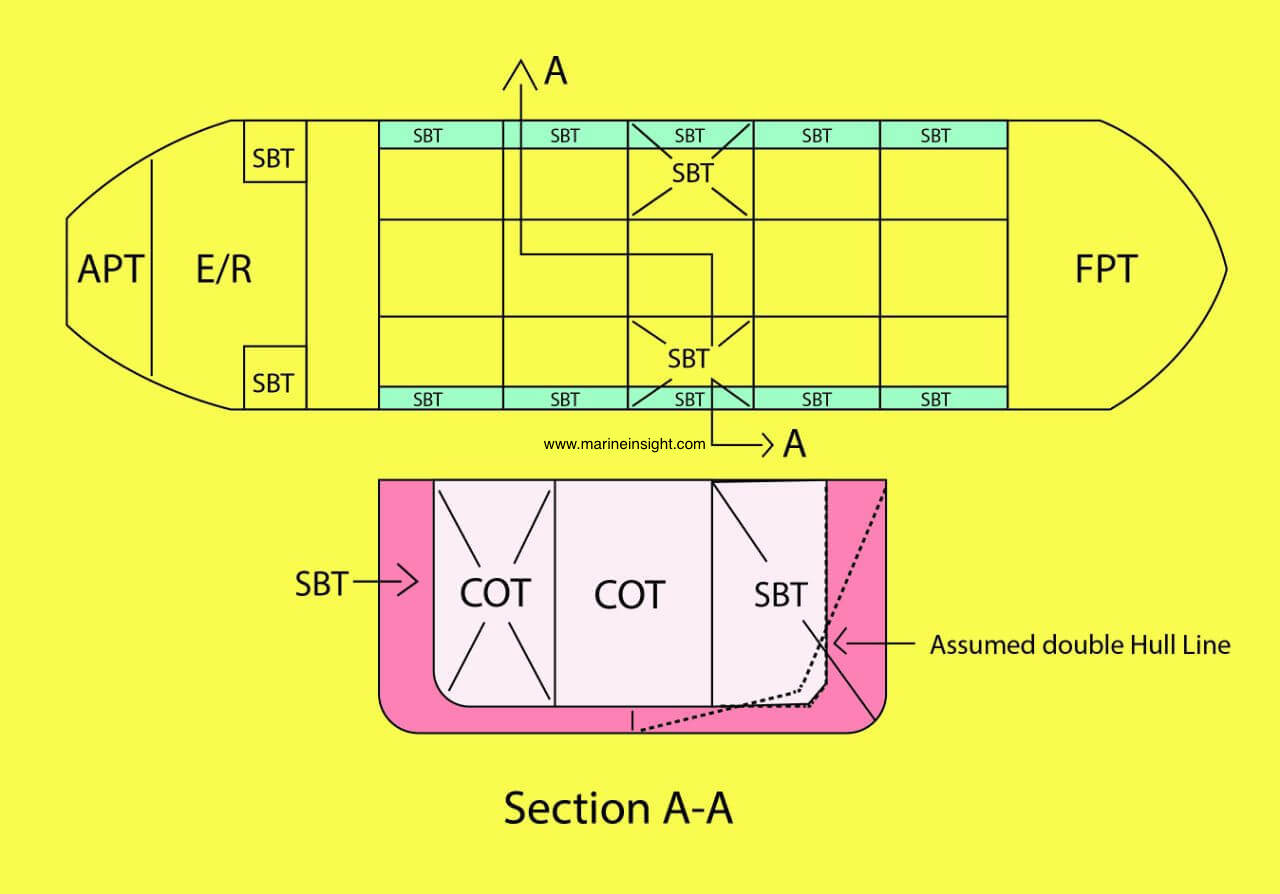

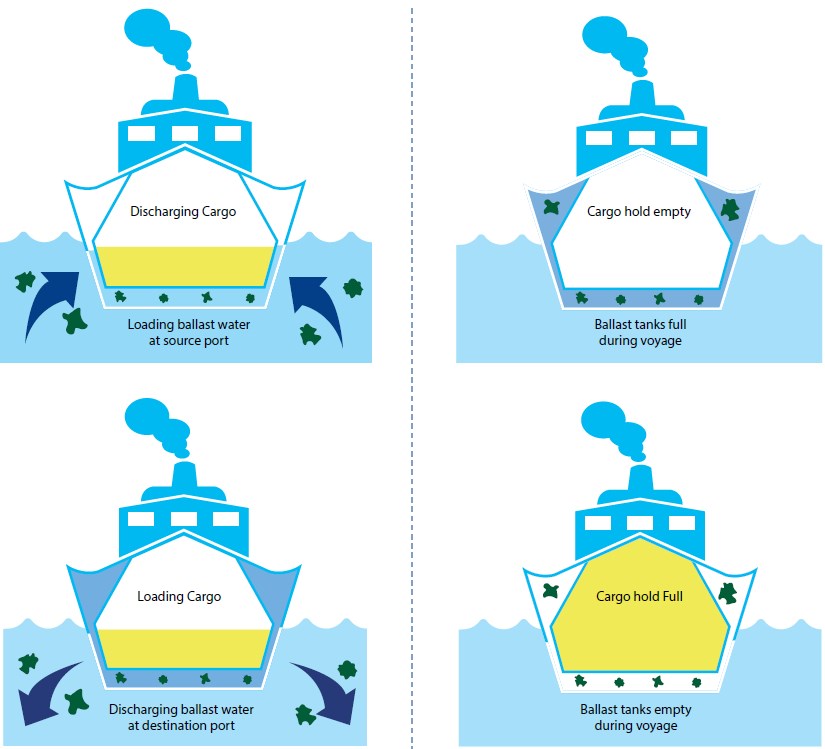

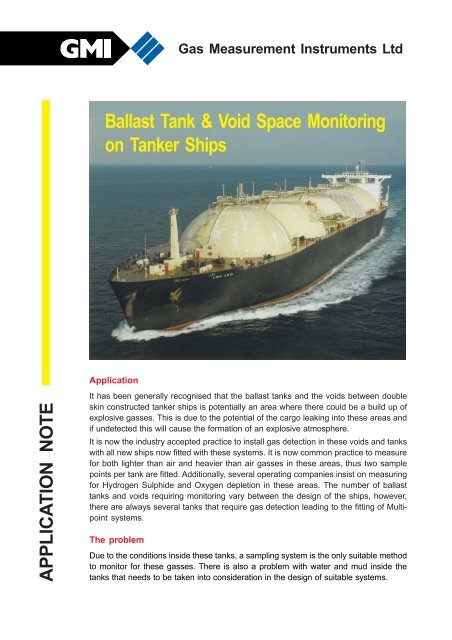

To give you an offer with an estimated price and timeline for BWTS implementation design we should need to know. Management system certificate Ship design and engineering services for the global maritime industry. A ballast tank is a compartment within a boat ship or other floating structure that holds water which is used as ballast to provide hydrostatic stability for a vessel to reduce or control buoyancy as in a submarine to correct trim or list to provide a more even load distribution along the hull to reduce structural hogging or sagging stresses or to increase draft as in a semi-submersible.

Planned BWTS processing capacity - m3h. Sterilisation by heat can be a capital treatment for ballast water and waste heat from ships engines will be a good resource.

Not even a lick of paint.

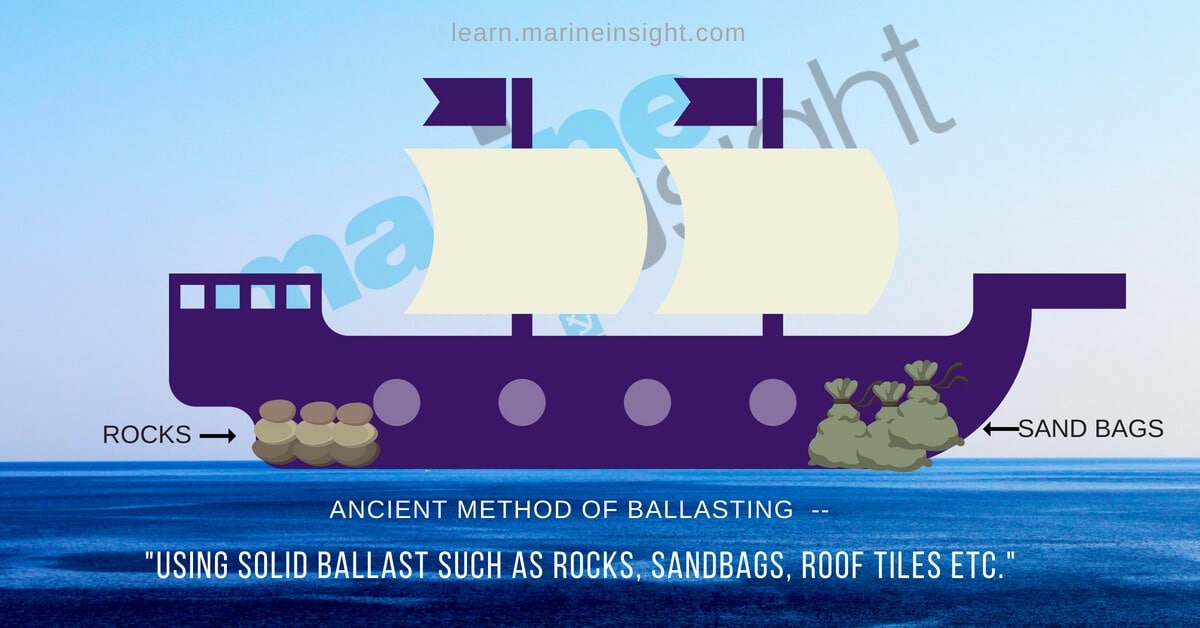

To flood the tank bars water is pumped into the tank with a high pressure water pump. This method uses new hull design for the ship or use of solid ballast TEU Twenty foot equivalent unit to provide unladen stability and trim without need for ballast water. A general profile and an initial overview of the ships propulsion. Navy has selected BIO-UV Group and its American engineering and servicing partner The Columbia Group to develop a Ballast Water Treatment System BWTS to equip. Based on the waste heat availability on an operational tanker a ballast water treatment system was envisaged including a. Tank capable of with standing a significant pressure increase 5 or so. To flood the tank bars water is pumped into the tank with a high pressure water pump. A ballast tank is a compartment within a boat ship or other floating structure that holds water which is used as ballast to provide hydrostatic stability for a vessel to reduce or control buoyancy as in a submarine to correct trim or list to provide a more even load distribution along the hull to reduce structural hogging or sagging stresses or to increase draft as in a semi-submersible. The capacity of each ballast pump - m3h.

A ballast tank is a compartment within a boat ship or other floating structure that holds water which is used as ballast to provide hydrostatic stability for a vessel to reduce or control buoyancy as in a submarine to correct trim or list to provide a more even load distribution along the hull to reduce structural hogging or sagging stresses or to increase draft as in a semi-submersible. In order to provide a suitable design staff ballast system control functions for testing simulation and research platform design a separate ballast system simulation software applications and has a strong research value. Water escaped through the crack when the ballast tank was overfilled. Because the air in. A ballast tank is a compartment within a boat ship or other floating structure that holds water which is used as ballast to provide hydrostatic stability for a vessel to reduce or control buoyancy as in a submarine to correct trim or list to provide a more even load distribution along the hull to reduce structural hogging or sagging stresses or to increase draft as in a semi-submersible. The Computer-Aided Design CAD files and all associated content posted to this website are created uploaded managed and owned by third-party users. Navy has selected BIO-UV Group and its American engineering and servicing partner The Columbia Group to develop a Ballast Water Treatment System BWTS to equip.

Post a Comment for "Ship Ballast System Design"